end mill cutter geometry

2 Grade Southern Pine Flooring. We left the old historic building and created a new and improved process.

End Mill Nomenclature Download Scientific Diagram

While end mills have traditionally had four cutting flutes recently cutters with three flutes and higher helix angles have been introduced.

. Sometimes called the flute. The original mill was located in Matthews Georgia. Free easy returns on millions of items.

An end mill is a type of milling cutter a cutting tool used in industrial milling applications. Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required. Contour machining is when an end mill machines around the workpiece at the same depth then sinks deeper repeats the operation shown in the image.

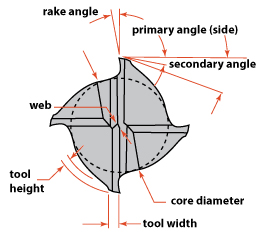

Free shipping on qualified orders. Reamer With few cutting edgesInexpensive production and re-grinding. The five important angles involved in the making of the millcutter are.

The space forming the end cutting edge which is used when feeding axially. Heel The back edge of the relieved land. Corner chamfer end mills have an angled cutting edge and are used where a specific radius size is not required.

The helix angle is the angle that an end mills helical cutting edge makes with the plane of its centreline. End mills are used in milling. They make the chips actually fly.

Brief Geometry of the Milling Cutter. It is the surface of the tooth trailing the cutting. Exotic geometries serve many functions and we cant possibly describe all the many variations out there in one article but lets go through a few of the more common examples.

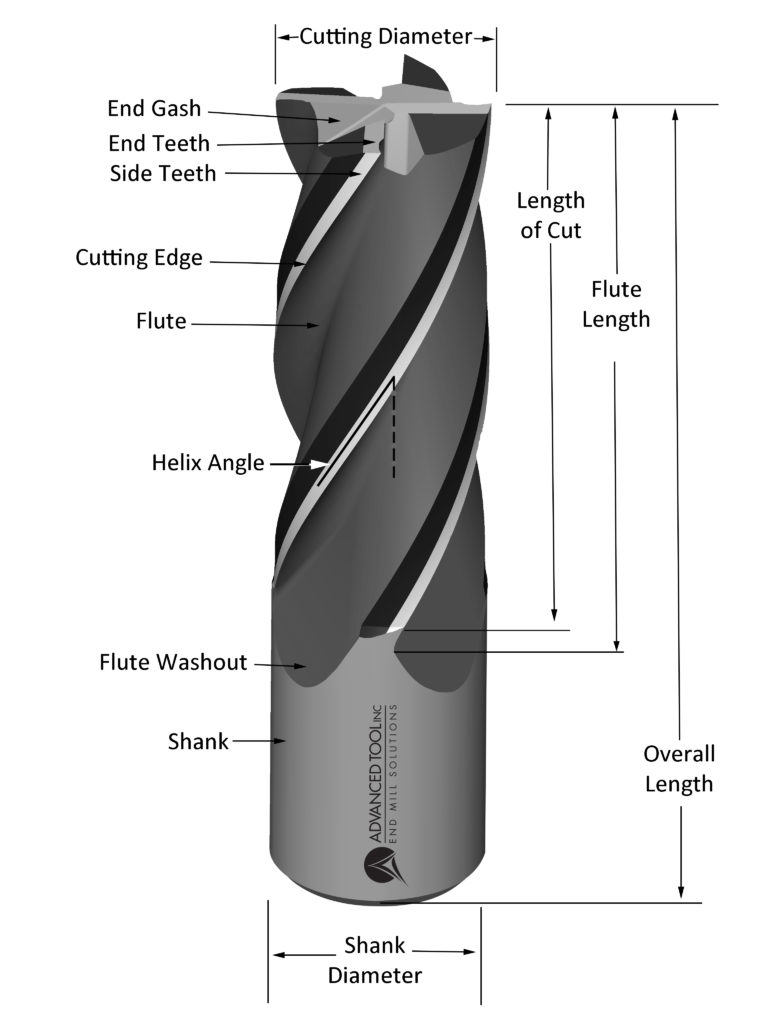

Each of these features has a direct influence on how the end mill will behave during a machining operation and on the cutting possibilities in. A higher helix angle means a larger rake angle thereby increasing sharpness to the tool. Mill 1-18 End Mills Cylindrical Shank Metric - 2613789.

These have one cutting edge ground right to the centre and thus can be used to drill directly into the workpiece when creating a recess. Solid Unfinished Heart Pine Wood Flooring. The final link to making good.

End mill cutter geometry. On the periphery the helix angle is the axial rake angle of the peripheral cutting edges. It is measured from the start of the necked portion to the bottom of the cutting end of the tool.

5 14 width Natural 6 79sf Limited square feet available - Call for current inventory. Gunpowder to fully meet the needs of the Confederate armies and still retained a surplus of 70000 pounds at the end of the war. The company hired Jones S.

Geometry is a huge determinant of end mill performance and there is a lot to cover. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep-pocket milling applications. End mill A multi-functional tool which has cutting edges on the periphery and an end face.

The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. Tommy Watkins started Watkins Milling Company over 50 years ago as a third-generation miller. Article is designed as a set of three interconnected elements.

It is distinguished from the drill bit in its application geometry and manufacture. While a drill bit can only cut in the axial direction most milling bits can cut in the radial direction. Upon completion of the canal enlargement in 1875 Augusta businessmen formed the Enterprise Manufacturing Company.

This geometrical feature ensures that the time intervals between cutting edge contact with the workpiece are varied rather than simultaneous with each tool rotation. Ad Browse discover thousands of brands. Davis to design a new mill.

This is illustrated in the. The space between cutting edges which provides chip space and resharpening capabilities. Gash width The width of the gash feature.

Side milling curved surface milling and drilling are possible only by one tool. Sibley Mill and Confederate Powder Works Chimney Rebecca Rogers. Those designed to cut axially are known as end mills.

End Mill Side Clearance Primary 1st angle 5- 9 Relief Adjacent to Cutting Edge Secondary 2nd angle 14-17 Relief Adjacent to Primary Angle Tertiary 3rd Additional Relief Provided Adjacent to the Secondary High Performance End Mills. Read customer reviews find best sellers. 34 Thickness Random lengths Square end trimmed.

The axial Rake angle of the cutter is equal to the Back Rack of the single point tool. Here are presented the purpose and the general. Contour machining is advantageous over copy machining because machining on level surfaces means that any.

Not all mills can cut axially. Hello everyone welcome to At-Man Unlimited. Copy machining is where the end mill moves linearly following the workpiece cross-sectional geometry.

Cutting edges are only on a top. In 1877 paying nearly 200000 Davis built a 3-story brick textile mill with a central stair tower situated. End Mills where the metal hits the work piece.

This model is also a 38-inch end mill with a 015 to 002-inch corner radius but it offers a 78-inch length of cut. - Click below to read more. Due to strict government regulations and a building over 100 years old we built a new facility in 2016 on our family land.

Types geometry and measurement of tool parameters of single flute end mill cutters. In 1873 the Granite Mill had an addition built on its west end. A feature on a variety of high performance end mills variable helix or variable pitch geometry is a subtle alteration to standard end mill geometry.

Used to carve a full-diameter 03-inch slot at 4200 rpm and 25 ipm this tool also achieves about 31 minutes of cutting. Gash angle The relief angle of the gash feature. Both types provide longer tool life than square end mills.

The radial Rake angle of the milling cutter is equal to the side rake of the single point tool. The Federal Government confiscated the powder works land and sold it between. Recommended Starting Feed per Tooth Fz in Relation to of Radial Engagement ae.

Sibley Mill and Confederate Powder Works Chimney Historic Augusta Inc. A cutting tool for making inside wall of a drilled hole smooth and accurate.

End Mills Cad Cam Engineering Worldwide

Walter Advance Line Of Milling Cutters Walter Prototyp Youtube

End Mill An Overview Sciencedirect Topics

Geometry Of A Standard End Mill Download Scientific Diagram

Hss Endmill Pt Metro Rekayasa Indonesia

Ball End Milling Cutter Geometry 16 Download Scientific Diagram

Endmill Selection Guide Redline Tools Redline Tools

Hss Endmill Pt Metro Rekayasa Indonesia

End Mill An Overview Sciencedirect Topics

End Mill Terminology Mitsubishi Materials Corporation

Illustration Of Ball End Milling Cutter Geometry A C And The Cutter Download Scientific Diagram

Sem Image Of The Micro End Mill Clearly Indicating The Tool Geometry Download Scientific Diagram

Two Flute End Mill Cutter Geometry Front View Download Scientific Diagram

Two Flute End Mill Cutter Geometry Centre Cutting Type Download Scientific Diagram

Technical Information Destiny Tool